Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Tilley Product Number

- CASE Ingredients Functions

- Industrial Additives Functions

- Technologies

- Product Families

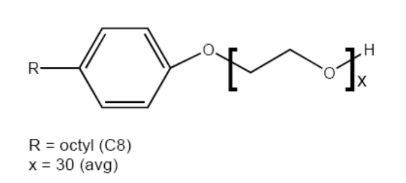

- Chemical Structure

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Industrial Additives Features

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Industrial Additives End Use

Properties

- Physical Form

- Soluble In

- Appearance

- Pale yellow liquid

- Soluble in

- Water

- Miscible In

- Most polar organic solvent

- Insoluble in

- Aliphatic hydrocarbons, Aromatic hydrocarbons

- Stable in

- Alkaline solutions, Acidic solutions

- Compatible with

- Nonionic surfactants, Cationic surfactants, Anionic surfactants

- Physical Properties

Value Units Test Method / Conditions Actives 70 wt% Cloud Point⁽¹⁾ min. 100 °C HLB⁽²⁾ 17.3 Moles EO 30 Pour Point⁽³⁾ -7 °C pH (5% aqueous solution) 7 Viscosity (at 25°C) 470 cP Density (at 25°C) 1.092 g/mL Critical Micelle Concentration⁽⁵⁾ 1916 Surface Tension⁽⁶⁾ 49 mN/m Foam Height⁽⁷⁾ 103/25 mm - Notes

- (¹) Cloud point: °C, 1 wt% actives aqueous solution

- (²) HLB Range: <10 w/o emulsifier, >10 o/w emulsifier, 10-15 good wetting, 12-15 detergents

- (³) Pour point: °C

- (⁴) Appearance at 25°C

- (⁵) Critical Micelle Concentration: ppm at 25°C

- (⁶) Surface tension: dynes/cm at 1% actives, 25°C

- (⁷) Ross-Miles foam height: mm at 0.1 wt% actives, 25°C, initial / 5 minute

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Storage & Handling

- Storage Information

- Storage

- To avoid discoloration, do not store in copper, copper alloys (brass, bronze), zinc, or galvanized iron.

- Store the products under nitrogen to avoid degradation, which causes undesirable color and odor.

- Store under air (without nitrogen blanket) only for short-term storage, when the temperature is less than 90°F (32°C). Slow degradation will occur under air storage. A desiccant unit may be installed in the vent line to dry incoming air.

- Heated storage and handling facilities may not be required for certain surfactants. Check the Safety Data Sheet or Technical Data Sheet for the pour point of the surfactant to determine whether heating is required for handling the product.

Handling- Standard all-iron valves and centrifugal pumps are commonly used for product transfer service. Ball valves with Teflon® seals can be used for “on-off” valves.

- All DOW surfactants, including both aqueous blends and 100% active materials, should be well mixed before use.

- If the surfactant has been subjected to temperatures at or near the published pour point, the product may freeze. Heavier mole weight fractions may settle at temperatures slightly higher than the pour point. This can be seen as sedimentation at the bottom of the container, and a lower cloud point may be observed. Should this happen, use heat and agitation to ensure the material is homogenous prior to use.

- When heating the surfactant, use mild heating, preferably with circulation or agitation, as surfactants are subject to discoloration when overheated. Heat with warm water or low-watt density electrical heating tape, so that the container temperature will not exceed 50°C (122°F).

- Low-pressure steam is acceptable, as long as circulation or agitation is provided. Avoid bayonet heaters because high temperatures can be generated on their heating surfaces. After the product has been heated, it should be mixed thoroughly to ensure uniformity of physical properties.

- Note : TRITONTM DF-20 surfactant can be irreparably damaged by freezing, so heating and remixing will not likely be effective. Frozen TRITONTM DF-20 Surfactant material should be replaced by new product.

- It is also not unusual for Dow Surfactants to develop some haze after storage at room temperature caused by higher molecular weight fractions solidifying and settling out of solution. If the material is heated and mixed thoroughly it should have no impact on the final performance of the material or the formulation. The suggested heating temperature is between 45°-50°C.

- If only part of a drum is used, then some agitation (such as provided by a typical drum roller) with slight heat should address the issue. If the entire drum will be used, then this pre-mixing should not be necessary as it will mix in the formulation.