Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Country of Origin

- INCI Name

- Ingredient Name

- Tilley Product Number

- Cleaning Ingredients Functions

- Cosmetic Ingredients Functions

- Food Ingredients Functions

- Pharma & Nutraceuticals Functions

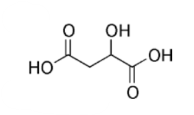

- Molecular formula

- C₄H₆O₅

- Technologies

- Product Families

- Chemical Structure

Features & Benefits

- Labeling Claims

- Food Ingredients Features

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

- Product Uses

- DL-Malic Acid, the natural acid constituent of apple, finds wide application in the food industry. Due to its compatibility with all types of flavour, the flavour enhancing property, the sharp, lingering acid taste and the high water solubility nature, it is ideally suited for the preparation of Juices, Soft drinks, Cider and Wines. Its’ non-hygroscopic, free flowing nature, makes it the preferred acid for dry squash juice mixes.

- When used in sugar confectionery, the low melting point of DL-Malic Acid gives greater clarity to the finished product. In cheese preparation, it increases the product yield.

- DL-Malic Acid is used in paneer preparation

- In diet products, it suppresses the bitter after taste of artificial sweeteners and reduces the amount needed, without affecting the sweetness.

- In fruit and vegetable canning, DL-Malic Acid is used for pH adjustment.

- In the edible oil processing/refining it is used to remove and control traces of metal impurities and as a synergist in admixture with antioxidants, to control rancidity.

- DL-Malic Acid is also used in Pharmaceuticals, Cosmetics, Metal cleaning and Textile finishing.

Properties

- Physical Form

- Soluble In

- Appearance

- White/crystalline/granular/fine granular/powder

- Typical Properties

Value Units Test Method / Conditions Molecular Weight 134.09 - - Particle Size Distribution (granulometry, through US 10 mesh) 100 % - Particle Size Distribution (granulometry through US 50 mesh) max. 10 % - Particle Size Distribution (fine granular through US 25 mesh) min. 99 % - Particle Size Distribution (fine granular through US 100 mesh) max. 5 % - Particle Size Distribution (powder, passing through USS 50mesh) min. 75 % - - Specifications

Value Units Test Method / Conditions Assay Content (on dry basis) min. 99.5 wt % Titrimetry Malic Acid Content max. 0.05 wt % Fumaric Acid Content max. 1 wt % Residue on Ignition (Sulphated Ash) max. 0.1 wt % Optical Rotation - 0.1 to 0.1 [α]²⁵ᵒD Conform to FCC 10 Lead Content max. 2 ppm - Insoluble Matter (Water) max. 0.1 wt % Moisture (by Loss on Drying) max. 0.3 wt % Heavy Metal Content (as lead) max. 5 ppm - Arsenic Content max. 1 ppm - Mercury Content max. 1 ppm - Cadmium Content max. 1.5 ppm -

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Packaging & Availability

- Packaging Type

- Packaging Information

- PE lined, PE laminated HDPE bag – 15 & 25 Kg

- PP laminated 4 ply Paper Bag – 25 Kg

- Fibre drum with PE liner – 30 Kg

- 500, 800 & 1000 Kg Bulk bag with inner liner

Full Container Load (FCL):

Palletised and Stretch Wrapped

1.Packed in 25 Kg HDPE Bags- 40 X 25 Kg Bags / Pallet = 1.0 MT

- 36 X 25 Kg Bags / Pallet = 0.9 MT

- 0.9 MT X 20 Pallets = 18 MT / FCL

- 1.0 MT X 10 Pallets and

- 0.9 MT x 10 Pallets = 19 MT / FCL

2. Packed in 15 Kg HDPE Bags

- 64 X 15 Kg Bags / Pallet = 0.96 MT

- 60 X 15 Kg Bags / Pallet = 0.90 MT

- 0.96MT X 16 Pallets & 0.9MT X 4 Pallets=18.96 MT/FCL

3.Packed in 25 Kg Paper Bags

- 36 X 25 Kg Paper Bags / Pallet = 0.9 MT

- 32 X 25 Kg Paper Bags / Pallet = 0.8 MT

- 0.9 MT X 10 Pallets & 0.8 MT x 10 Pallets = 17 MT /FCL

4. Packed in Fibre Drums

- 18 X 30 Kg fibre drums / Pallet

- = 0.54 MT X 20 Pallets = 10.8 MT / FCL

5. Packed in Bulk Bags

- 30 X 500 Kg bulk bag on pallets = 15 MT / FCL

- 20 X 800 Kg bulk bag on pallets = 16 MT / FCL

- 20 X 1000 Kg bulk bag on pallets = 20 MT / FCL

Storage & Handling

- Shelf Life

- 24 months

- Shelf Life and Storage Condition

- It must be stored in ambient temperature, properly covered in a dry well ventilated place.

- Shelf Life: 24 months from the date of production under recommended storage conditions.